Mold Engraving

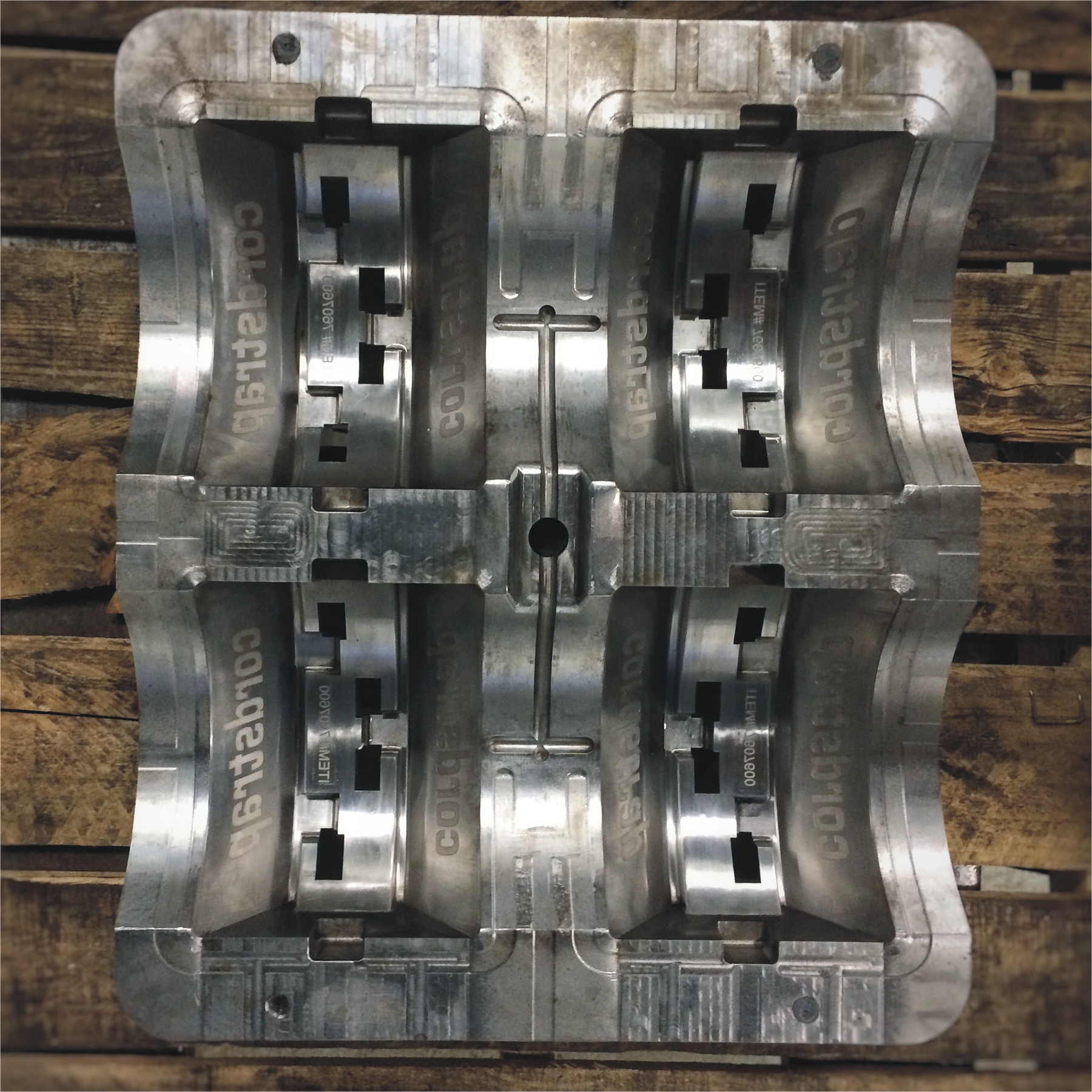

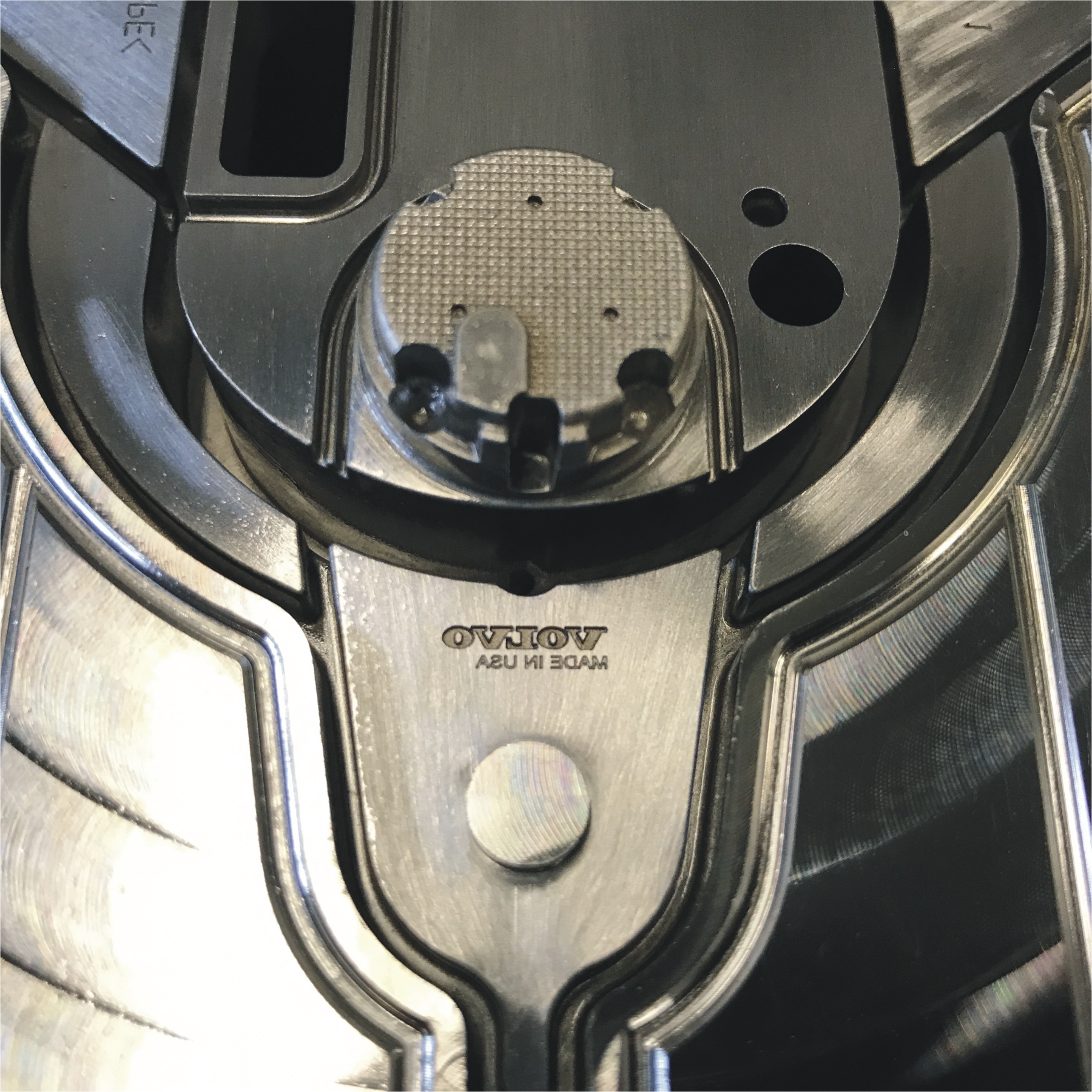

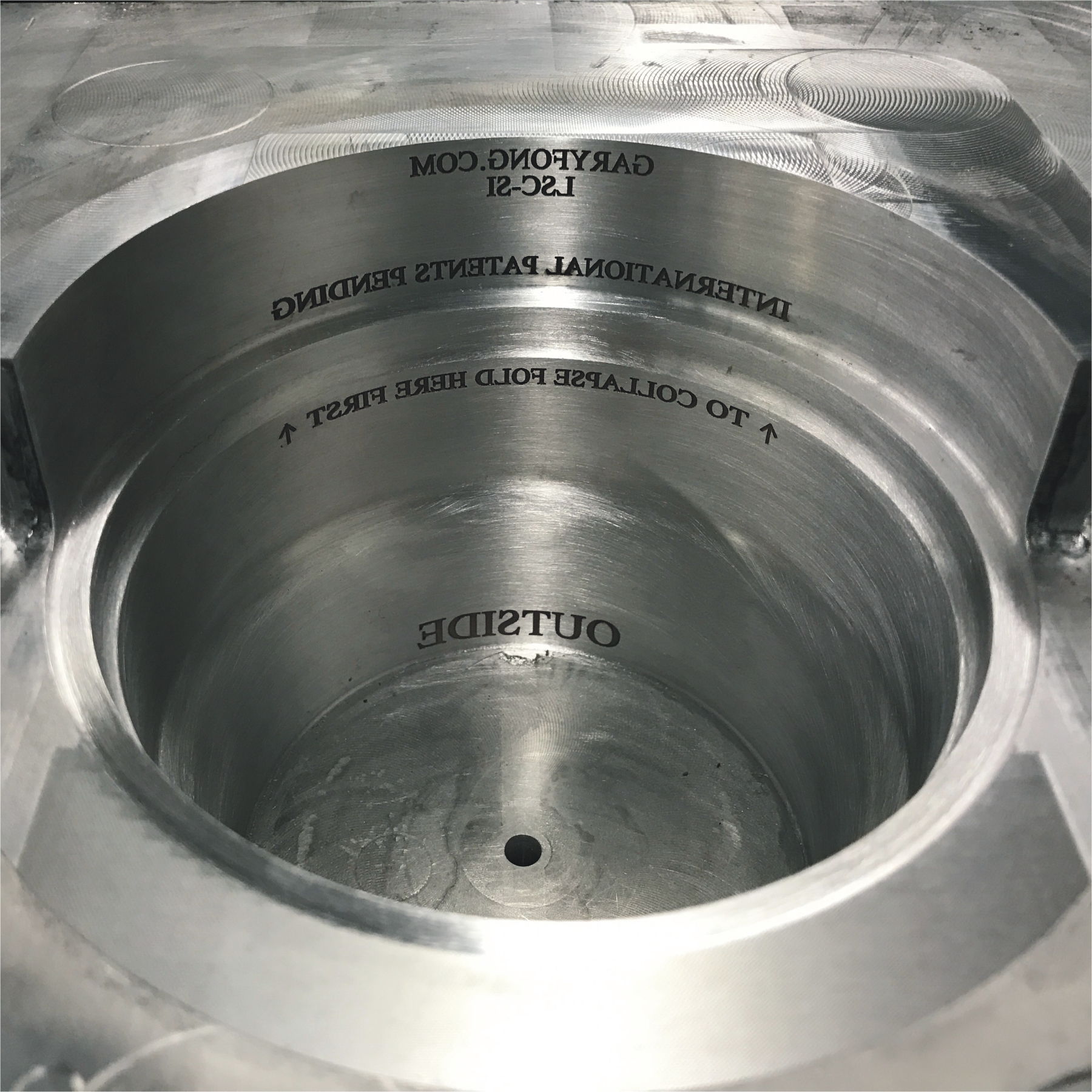

Plastic Injection Mold Cavities and Inserts

CNC and EDM engraving into virtually any type of mold component. From aluminum blow molds, hardened H13 mold halves, Mold Max® cores, to carbide inserts, our equipment is capable of machining a variety of materials including exotics.

- Multi-cavity tools to prototype molds

- Able to machine carbide

- Quick turn around times

- EDM tank capacity for larger tools